|

Bar OD - mm (Min & Max) |

Bar Length - mm (Min & Max) |

|---|---|

| 20 - 120 | 700 - 4700 |

| 130 - 210 | 700 - 4700 |

| 220 - 370 | 900 - 4700 |

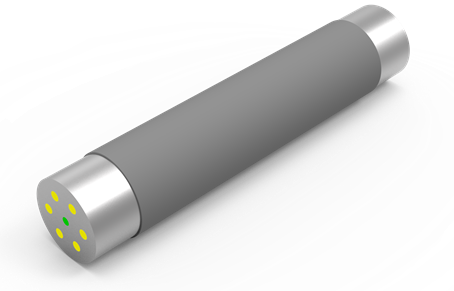

At Special Steels, we aim to create value across the entire manufacturing chain by investing in capital equipment that makes a measurable difference to our customers. Our machine preparation equipment is dedicated to facing, centring drilling and tapping so that material arrives in a ready to be machined condition on our customers’ floors.

Machine preparation shortens lead times and adds valuable hours to critical component manufacturing for customers who rely on just-in-time supply chain management.

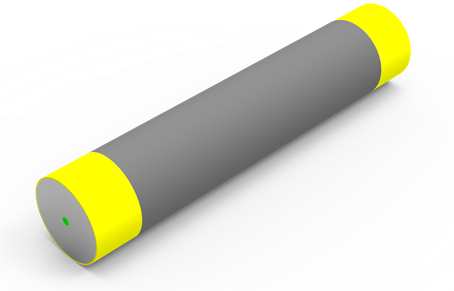

Allowing us to face, centre, drill and tap materials before they arrive at your factory reduces your manufacturing lead time.

When ordering any round bar or hollow bar product, request machine preparation as a value-added service and enjoy shorter timeframes on manufacturing projects.

|

Bar OD - mm (Min & Max) |

Bar Length - mm (Min & Max) |

|---|---|

| 20 - 120 | 700 - 4700 |

| 130 - 210 | 700 - 4700 |

| 220 - 370 | 900 - 4700 |

| Available Sizes - mm | Form |

|---|---|

| 4 x 10 | A |

| 5 x 12.5 | A |

| 8 x 20 | A |

|

Bar OD - mm (Min & Max) |

Chuck Prep Length - mm (Min & Max) |

Min Bar Length - mm (Min & Max) |

|---|---|---|

| 20 - 210 | 10 - 50 | 700 - 4700 |

| 20 - 190 | 10 - 100 | 700 - 4700 |

| 210 - 370 | 10 -70 | 900 - 4700 |

| Available Sizes |

|---|

| M12 |

| M16 |

| M20 |

| M24 |

| M30 |

Additional value-added services, Robot Welder and Form Tools for Face & Centre